數控焊接設備的潤滑油更換依據指標

來(lái)源:http://www.aplwebs.com/ 發(fā)布時(shí)間:2023-05-06 瀏覽次數:0

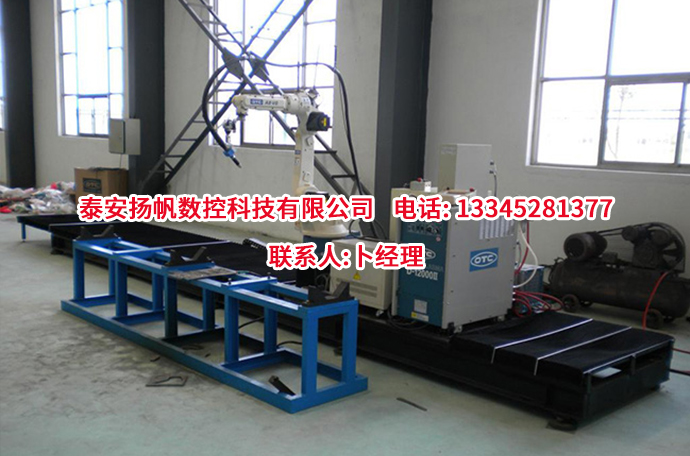

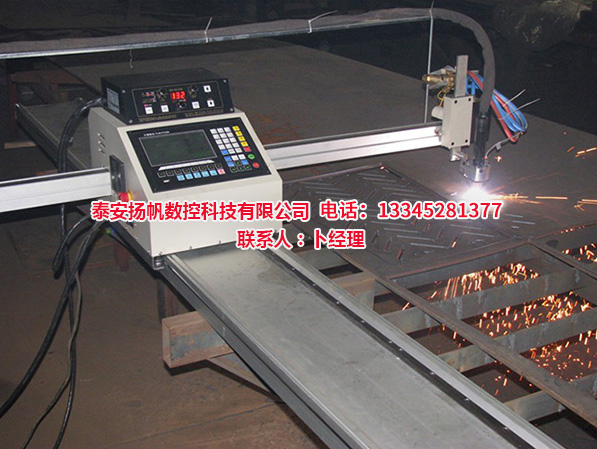

數控焊接設備是一種自動(dòng)化焊接設備,它采用計算機控制進(jìn)行焊接操作,可以實(shí)現高精度、率、高質(zhì)量的焊接。數控焊接設備基本由焊接機器人、控制系統、加工程序等三個(gè)部分組成。廣泛應用于機械制造、建筑、汽車(chē)、航空、航天等領(lǐng)域,能夠滿(mǎn)足不同領(lǐng)域的精度要求和生產(chǎn)效率需求。

CNC welding equipment is an automated welding equipment that uses computer control for welding operations, which can achieve high-precision, high-efficiency, and high-quality welding. CNC welding equipment is basically composed of three parts: welding robots, control systems, and processing programs. Widely used in mechanical manufacturing, construction, automotive, aviation, aerospace and other fields, it can meet the accuracy requirements and production efficiency requirements of different fields.

數控焊接設備需要根據設備使用時(shí)間、潤滑油的使用情況、環(huán)境和工況等不同因素來(lái)確定更換潤滑油的時(shí)機。一般來(lái)說(shuō),數控焊接設備的潤滑油應該定期更換,以保持設備的正常運行和延長(cháng)機器壽命。具體更換時(shí)間間隔因設備類(lèi)型和工況不同而異。

CNC welding equipment needs to determine the timing of lubricating oil replacement based on different factors such as equipment usage time, lubricant usage, environment, and working conditions. Generally speaking, the lubricating oil of CNC welding equipment should be replaced regularly to maintain the normal operation of the equipment and extend the lifespan of the machine. The specific replacement interval varies depending on the type of equipment and operating conditions.

當潤滑油使用一定時(shí)間后,會(huì )因為吸收了灰塵、雜質(zhì)等污染物質(zhì),油脂有變質(zhì)和氧化的可能,從而導致潤滑效果變差,甚會(huì )加速機器的磨損,從而影響設備的生產(chǎn)效率和質(zhì)量。因此,山東數控焊接設備的潤滑油更換可以依據以下指標來(lái)確定:

When lubricating oil is used for a certain period of time, it may deteriorate and oxidize due to the absorption of pollutants such as dust and impurities, leading to poor lubrication effect and even accelerating machine wear, thereby affecting the production efficiency and quality of the equipment. Therefore, the replacement of lubricating oil for Shandong CNC welding equipment can be determined based on the following indicators:

時(shí)間:一般潤滑油更換周期為數月半年。工作負荷:如果機器長(cháng)時(shí)間在高負荷運行,更換潤滑油的頻率應當相應增加。

Time: The general lubricating oil replacement cycle is several months to six months. Workload: If the machine is operating at high load for a long time, the frequency of lubricating oil replacement should increase accordingly.

溫度:如果運行環(huán)境溫度高,更換潤滑油的頻率應當相應增加。

Temperature: If the operating environment temperature is high, the frequency of lubricating oil replacement should increase accordingly.

操作環(huán)境:如果設備工作在惡劣的工作環(huán)境下,例如高溫、潮濕等,潤滑油的更換頻率應當相應增加。

Operating environment: If the equipment operates in harsh working conditions, such as high temperature, humidity, etc., the frequency of lubricating oil replacement should be correspondingly increased.

總之,根據設備的使用情況和潤滑油的使用情況,定期更換潤滑油可以保證設備的正常運行和延長(cháng)設備的使用壽命。更多相關(guān)內容就來(lái)我們網(wǎng)站http://www.aplwebs.com咨詢(xún)吧!

In summary, based on the usage of the equipment and lubricating oil, regular replacement of lubricating oil can ensure the normal operation of the equipment and extend its service life. For more related content, come to our website http://www.aplwebs.com Consult!

上一篇:數控切割機日常使用的技巧

下一篇:直縫專(zhuān)機可焊接什么以及注意事項